Understanding Keycap Materials: ABS, PBT, and POM

Posted by ISAAC ROSEN

Understanding Keycap Materials: ABS, PBT, and POM

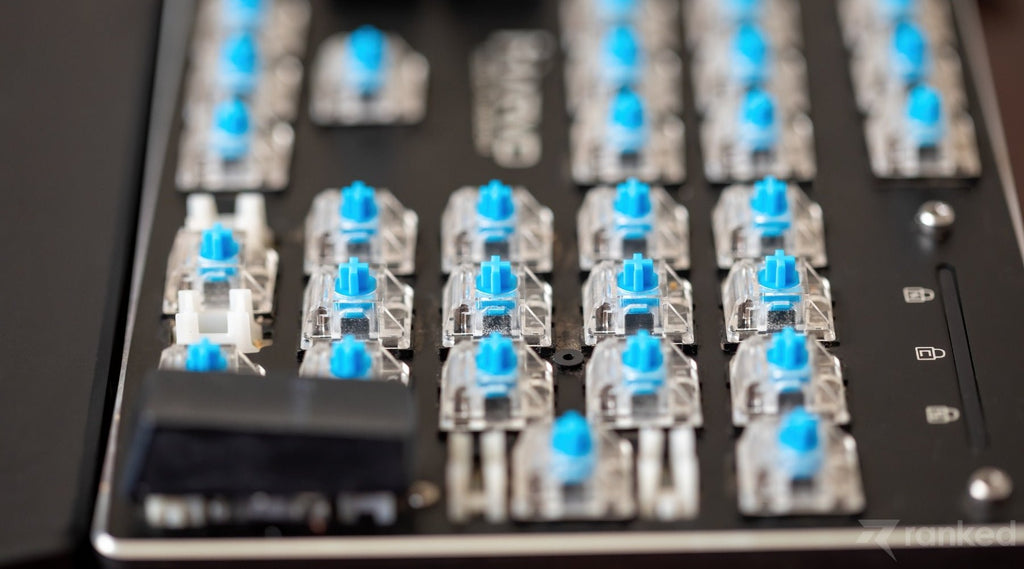

If you're a mechanical keyboard enthusiast, you know that the keycaps you use can have a significant impact on your typing experience. Keycaps come in a variety of materials, but the most common are ABS, PBT, and POM. Each material has its own set of advantages and disadvantages, and choosing the right one can make a big difference in how your keyboard feels and performs.

ABS Keycaps

ABS, or acrylonitrile-butadiene-styrene, is one of the most commonly used materials for keycaps due to its toughness, impact resistance, and low cost. It is a thermoplastic polymer with a melting point temperature of around 105°C (221°F). ABS keycaps are easy to manufacture and can be produced in a wide range of colors and styles, making them a popular choice for both standard and custom mechanical keyboards.

One of the main advantages of ABS keycaps is that they have a smooth, slightly shiny finish that feels great under your fingers. This is due to the fact that ABS keycaps have a low coefficient of friction, which means they are easy to slide across and have a tactile feedback that is preferred by many users. Additionally, ABS is known for its excellent light transmission, which makes it a popular choice for backlit keyboards.

In fact, ABS is the most common plastic used for backlit keycaps. The smooth surface of ABS allows light to pass through easily, resulting in a bright and uniform glow across the entire keycap. This is why many backlit mechanical keyboards come with ABS keycaps, as they are a reliable and cost-effective solution for achieving a high-quality backlit effect.

However, one potential issue with ABS keycaps is that they are prone to "shining" or "smoothness," which means that the surface of the keycaps can become slick and slippery with extended use. This can make it difficult to maintain a good grip on the keys and can affect your typing accuracy and speed. Additionally, ABS keycaps can be affected by UV light, which can cause them to fade or yellow over time.

Despite these potential downsides, ABS keycaps remain a popular choice due to their affordability, availability, and suitability for backlit keyboards. While they may not be as durable as other materials like PBT or POM, ABS keycaps can still provide a great typing experience and are a great option for those looking for an entry-level keycap material.

PBT Keycaps

PBT, or polybutylene terephthalate, is a thermoplastic polymer that's become increasingly popular for keycaps in recent years. PBT keycaps are known for their durability, resistance to shine, and matte finish. They have a melting point temperature of around 223°C (433°F).

PBT keycaps are often thicker and more textured than ABS keycaps, which can give them a more substantial feel. They are also more resistant to shine and wear than ABS keycaps and can maintain their texture and feel for longer periods of time. PBT keycaps are generally available in a more muted color palette than ABS keycaps, which are known for their vibrant colors.

While PBT keycaps are available in a range of colors, they tend to be less vibrant and have a more pastel-like appearance than their ABS counterparts. This is because PBT is less receptive to dyes and pigments than ABS, which can result in a more subdued color palette. However, some users prefer the more subtle color options of PBT keycaps, as they can give a more understated and professional look to a keyboard.

It's worth noting that many keysets that claim to be made of PBT are actually a blend of PBT and ABS. The ABS is typically added to make the keycaps easier to manufacture and to provide additional strength and impact resistance. Keycaps that are 50% ABS and 50% PBT are not uncommon, and high concentrations of PBT (>95%) are relatively rare. Despite this, PBT keycaps are still generally considered to be a more durable and higher quality option than ABS keycaps.

In summary, PBT keycaps offer a number of advantages over ABS keycaps, including increased durability, resistance to shine, and a more matte finish. They can also have a more muted color palette than ABS keycaps, but some users prefer this understated look. Additionally, it's worth noting that many keysets that claim to be made of PBT are actually a blend of PBT and ABS.

POM Keycaps

POM, or polyoxymethylene, is a thermoplastic polymer that's occasionally used for keycaps. POM keycaps are known for their smooth surface texture and resistance to wear and tear. They have a high melting point temperature of around 175°C (347°F).

POM keycaps have a hard, dense feel that's similar to that of ABS keycaps, but they're less prone to shine or wear down over time. They have a smooth surface that feels slightly softer to the touch than PBT keycaps. While POM keycaps can be difficult to manufacture and color, they offer a unique and high-quality feel that is favored by many keyboard enthusiasts.

One potential disadvantage of POM keycaps is that they can be more expensive than both ABS and PBT keycaps. Additionally, they're less commonly available than either ABS or PBT keycaps, so there may be fewer options available for customization. POM keycaps also tend to be denser than other keycap materials, which some users may find uncomfortable or heavy.

Another challenge with POM keycaps is that they are difficult to color match. Because POM is not receptive to dyes and pigments, it's more challenging to achieve a consistent color across a set of keycaps. As a result, POM keycaps tend to be available in a limited range of colors, making it harder for users to find a color that matches their keyboard's design.

Despite these challenges, POM keycaps are still a popular choice for those who value their unique feel and durability. While they may not be as widely available as other keycap materials, POM keycaps can offer a high-quality typing experience that is unlike any other.

| Feature | ABS | PBT | POM |

|---|---|---|---|

| Melting point | Around 105°C (221°F) | Around 223°C (433°F) | Around 175°C (347°F) |

| Texture | Smooth, slightly shiny | More textured and matte | Smooth and hard |

| Price range | Lower cost | More expensive than ABS | More expensive than ABS and PBT |

| General feel | Smooth and slick | More substantial feel | Hard and dense feel |

| Wear or shine rate | Prone to shine or smoothness with extended use | Resistant to shine and wear | Resistant to shine or wear |

| Incidence of UV exposure | Prone to fading or yellowing over time | Less prone to fading or yellowing | Not affected by UV exposure |

| Additional nuggets | Excellent light transmission, making it a popular choice for backlit keyboards | Can have a more muted color palette than ABS keycaps | Limited color options and difficult to color match |

In summary, ABS keycaps are a popular choice due to their affordability, availability, and smooth feel, but can be prone to shine or smoothness and fading or yellowing over time. PBT keycaps are more expensive but more durable and resistant to shine or wear, and have a more substantial feel and matte finish. POM keycaps are more expensive and harder to manufacture, but offer a unique and high-quality feel, are resistant to wear or shine, and are not affected by UV exposure. Ultimately, the best keycap material for you will depend on your personal preferences and priorities.